Piping Stress Analysis Services

“At Conserve Solutions, our commitment is to deliver exceptional Piping Stress Analysis services, supported by a wealth of professional experience”

What is Piping Stress Analysis?

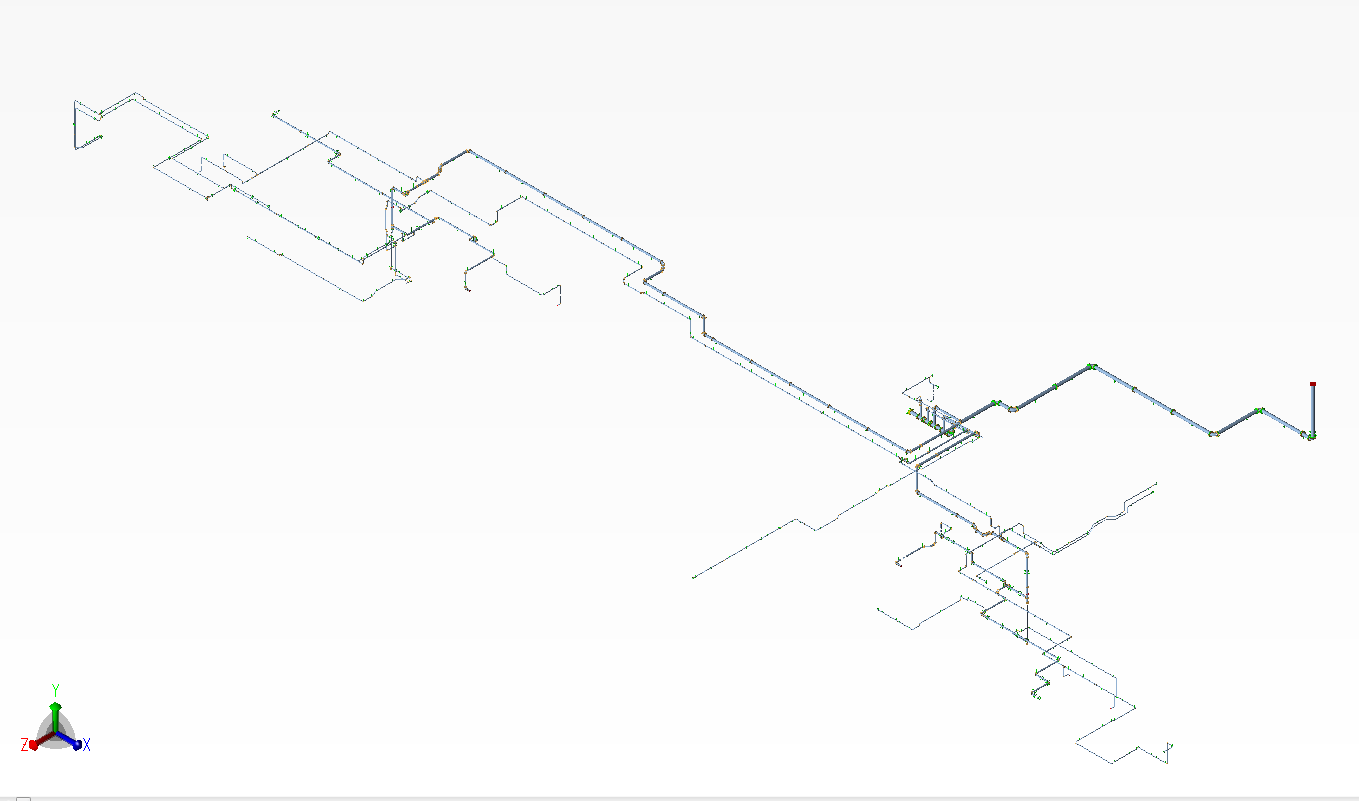

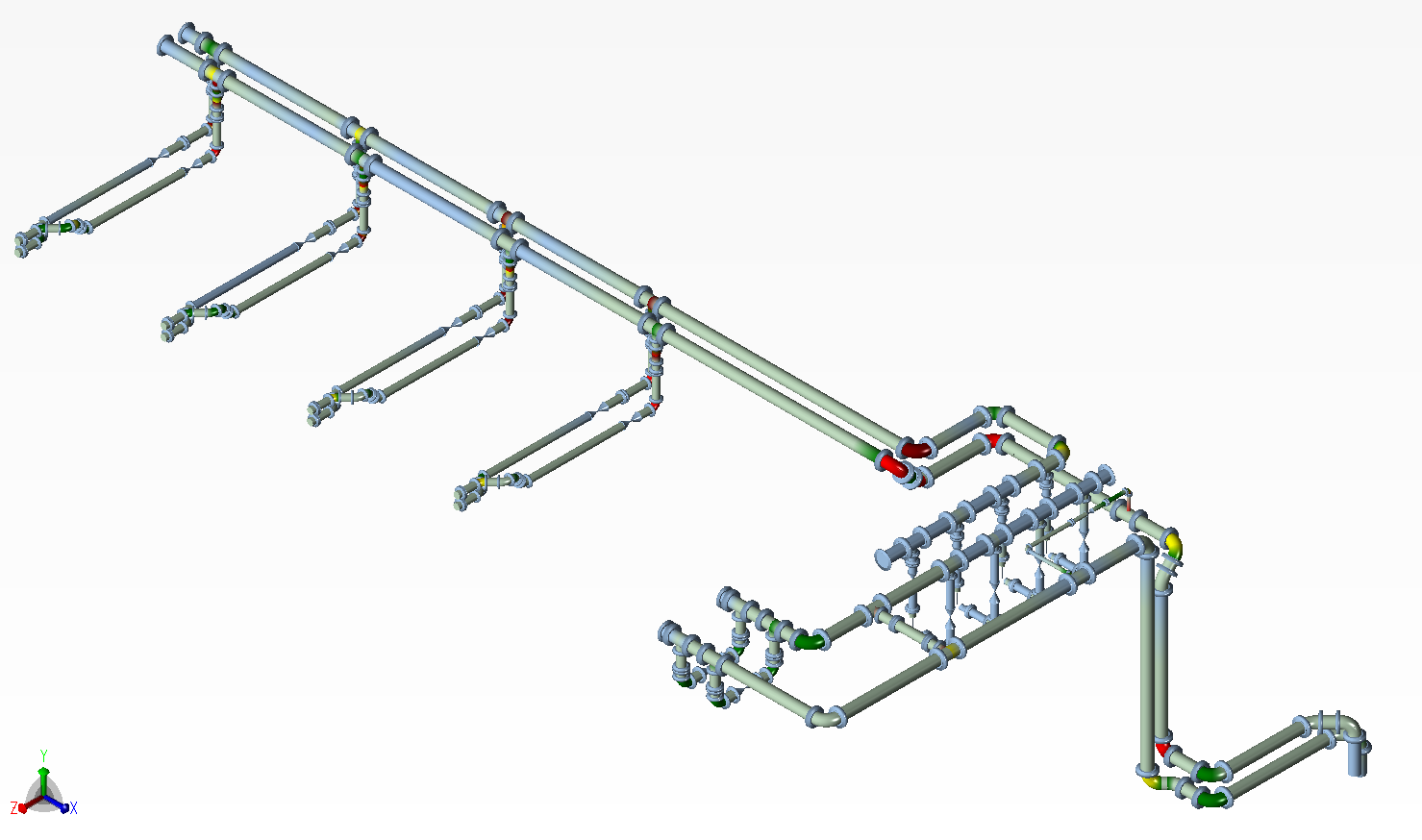

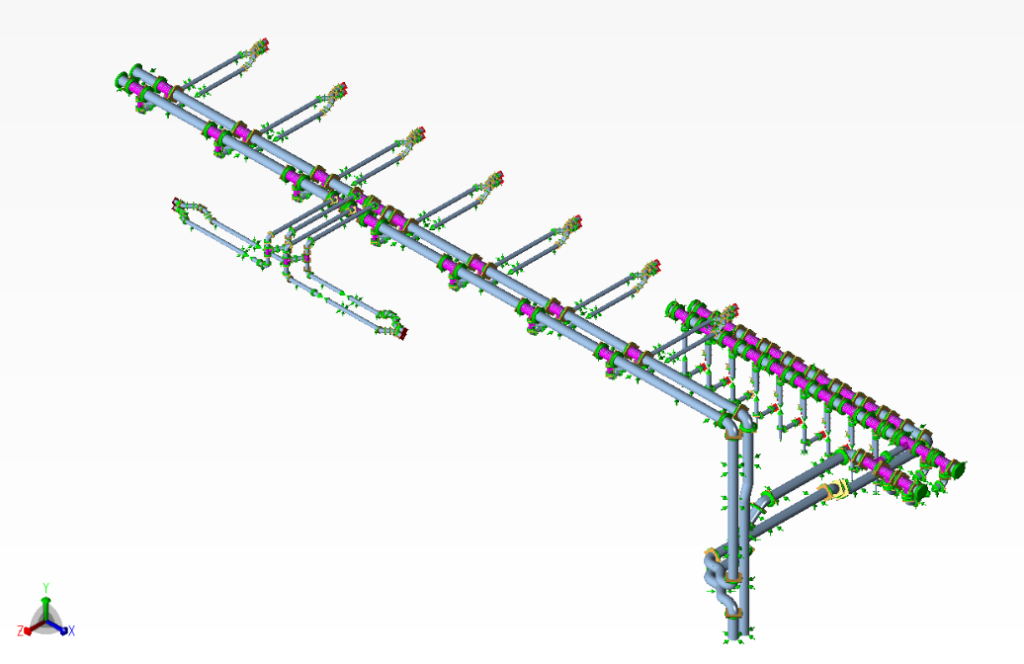

Piping Stress Analysis, commonly known as Stress Analysis, plays a pivotal role in the realms of mechanical and structural engineering. It encompasses the evaluation of how forces, pressures, temperatures, and external loads affect the structural integrity and functionality of a piping system. The key objective of Piping Stress Analysis is to validate those components such as pipes, fittings, and supports can withstand these stress factors, preventing excessive deformation, failures, and ensuring overall safety.

We Provide a Wide Range of Piping Stress Analysis

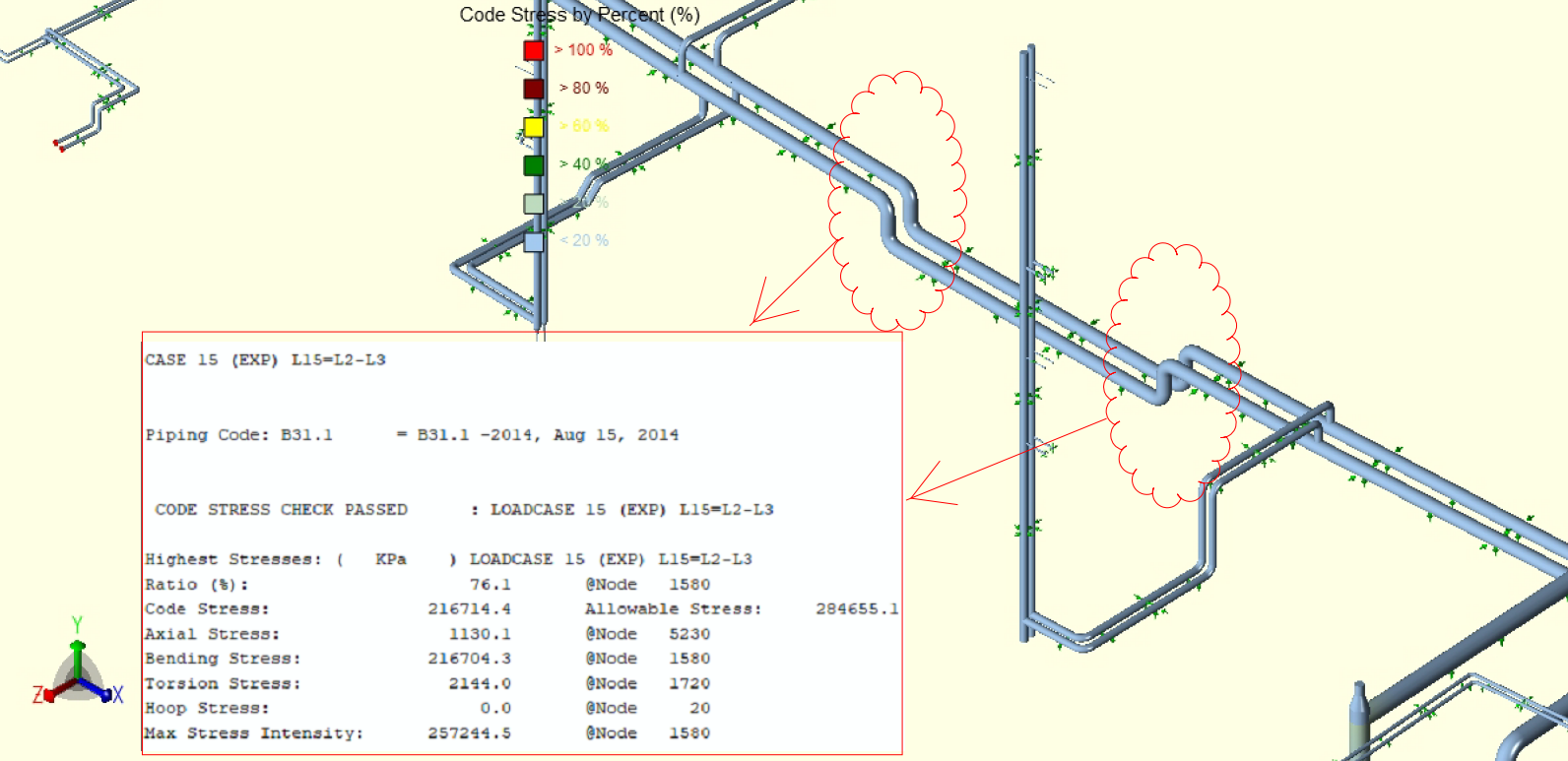

Static analysis

- Equivalent Static analysis (Dynamic)

- Pressure loading

- Occasional loading

- Thermal loading

Dynamic analysis

- Modal analysis

- Harmonic analysis

- Vibration analysis

- Time–history analysis

- Water hammer analysis

Our Tools Used for Stress Analysis

- CAESAR II, by Hexagon

- Auto pipe, by Bentley

- CAEPIPE, by SST USA

- PEPS, by DST Engineering

- Rohr2, by Sigma, Germany

- PASS/START-PROF

Why Choose Conserve Solutions?

Expertise and Experience:

Our team comprises seasoned professionals with extensive experience and in-depth knowledge in the field of piping stress analysis.

Tailored Solutions

Recognizing the unique characteristics of each project, our approach is carefully tailored with this understanding in mind. Our services are personalized to meet your specific requirements and objectives, whether it involves refining designs, improving efficiency, or ensuring the safety of your piping systems.

Unwavering Commitment to Excellence

At Conserve Solutions, our dedication to delivering top-notch piping stress analysis services remains resolute.

Comprehensive Analysis

Utilizing state-of-the-art tools and methodologies, we conduct thorough stress analyses on your piping systems. This process identifies potential issues and provides solutions to enhance performance and reliability.

Frequently Asked Questions?

Piping stress analysis is an engineering assessment that evaluates the effects of forces, pressures, and temperatures on piping systems. It is crucial to ensure the structural integrity, safety, and reliability of these systems, particularly in industries such as oil and gas, petrochemicals, and power generation.

Piping stress analysis should be contemplated during the design and engineering phase of a project, whenever modifications are made to existing systems, or if concerns arise about the integrity and performance of the piping.

Piping systems may undergo various stresses, including thermal stresses from temperature fluctuations, pressure-induced stresses, weight and gravity-related stresses, and vibration-induced stresses.

Piping stress analysis contributes to optimizing designs, preventing failures, improving system efficiency, and ensuring compliance with safety standards. Ultimately, it minimizes the risk of costly downtime and maintenance.

The timeframe for a piping stress analysis varies based on the complexity of the system and specific project requirements. It is advisable to consult with your service provider for a more accurate estimate.

Other Images