Oil & Gas Engineering Services – KSA

Oil & Gas Engineering

Services - KSA

Conserve showcases a diverse team of dedicated engineering professionals committed to delivering comprehensive Oil & Gas plant engineering design services, both offshore and onshore. Our expertise encompasses a wide spectrum, covering Process, Mechanical, Piping/Pipeline, Civil/Structural, Electrical, and Instrumentation and Control engineering solutions, along with Project Management Services.

We offer a range of engineering services tailored to meet the needs of our clients throughout various project stages.

Front-End Engineering and Design (FEED)

We offer preliminary engineering studies aimed at delineating the scope, objectives, and requirements of each project. By conducting these studies, we establish a solid framework that paves the way for seamless project execution, ensuring clarity and alignment from the outset.

Detailed Design and

Engineering (DED)

Our team excels in crafting detailed engineering designs that serve as the blueprint for turning conceptual ideas into tangible realities. With a focus on precision and efficiency, we transform abstract concepts into actionable plans that lay the foundation for successful project execution.

As-Built Engineering and Documentation

Our As-Built Engineering and Documentation service encompasses a meticulous approach to capturing and documenting the final state of the plant at the site. Leveraging the latest technologies and industry best practices such as 3DLasers Scanning Services, we update 3D models, drawings, and documents to reflect the as-built conditions accurately, ensuring alignment with the physical plant configuration.

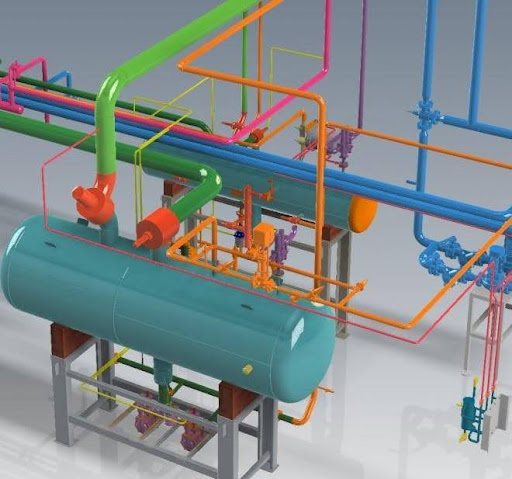

Plant 3D Modelling Services

- Project Setup as per client specs

- Catalog Generation / Creation

- Admin Services

- Plant 3D Modeling Services

- 3D Rendering Services | 3D Visualization Services

- Extraction of equipment layouts, general arrangement drawings, piping isometrics, nozzle orientation drawings, Structural, Instrumentation layout, fabrication drawings, and material take-off (MTO)/bill of materials (BOM).

Process Engineering

- Plant Feasibility/Concept study

- Hydraulic & Transient Analysis

- Process Simulation Services

- CFD Simulation – Thermal Comfort, Smoke Simulation, Flare Tower, Dispersion, Pumping Station, etc.

- PFD Generation, P&ID Generation

- Hazop/Hazid/SIL Support & Studies

Mechanical Engineering

- Design & Detailing of Static equipment like Pressure Vessels, Storage Tanks & Valves

- Design & Detailing of Rotary equipment like turbines, pumps, and compressors

- Mechanical Datasheets, Technical Specifications

- Material take off (MTO)

- HVAC Engineering

- Thermal and Fluid Flow Studies using Finite Element Analysis (FEA) and Computational fluid dynamics (CFD)

Piping/Pipeline Engineering

- Piping Design & Detail Engineering Services

- Hydraulic Analysis – Steady State and Transient Simulations

- Water Hammer or Surge Analysis

- Pipe Stress Static and dynamic Analysis, Pulsation analysis

- Cross-Country Oil and Gas Transmission Pipelines

- Flow Lines / Trunk Lines and Remote Header Facilities

- Wall Thickness Calculation, Material Selection, Detailing Services

- Piping MTO Services, GA Drawing Preparation

- Spool Drawing Preparation, Isometric Generation

Civil/Structural Engineering

- Structural Steel & RCC Supporting Supports Analysis, Design & Detailing

- Detailed Connection Design & Detailing

- Cast Unit Drawings/Bar Bending Schedule, Steel Single Part & Assembly Drawings

- Architectural design and detailing services

- Pre-stressed and Pre-Cast Concrete Details

- Civil Engineering services including Roads, Earthworks, Pipeline trenches etc.,

- Dynamic, In place & Transportation (Barge & Land), Blast and Lifting Analysis

- Fixed Platforms , Topsides, Jackets, Floating Platforms-FPSO

- Retaining Structures, Equipment / Machine Foundation, Pipe Rack Structures & Skid Supporting Structures, Modular Construction Solutions.

Electrical Engineering

- Loop & Hookup Drawings

- Electrical Layouts, Control Panel, JB, Wiring Details

- Installation Drawings & Layouts

- Lighting Design Calculation

- Load Flow Analysis, Short Circuit Analysis

- Protective device coordination

- Hormonic analysis

- Arc flash analysis

- CCTV Coverage study

Instrumentation & Control Engineering

- Control Panel Design and Fabricator Technical Support

- Instrument I/O Database

- Instrument Specification Sheets (Data Sheets)

- PLC/DCS Control System Design and Programming

- P&ID Design Development

- Plant Walk Throughs P&ID Documentation.

Codes and Standards Compliance

- API Standards

- ASME/ ASTM standards

- ANSI/ISA Standards

- AISC/ ACI standards

- SAES, SAMSS, SBC standards

- NFPA Standards

- NEC, IEEE standards

Why Choose Conserve Solutions?

Multidisciplinary Expertise

Our team possesses diverse skills in Process, Mechanical, Piping/Pipeline, Civil/Structural, Electrical, and Instrumentation and Control engineering in a single roof, ensuring a comprehensive approach to projects.

Innovative Solutions

We embrace the latest technologies and industry best practices, including 3D Laser Scanning Services, latest software applications to deliver cutting-edge and innovative solutions for the oil and gas sector.

End-to-End Services

From Front-End Engineering and Design (FEED) to Detailed Design and Engineering (DED), and As-Built Engineering and Documentation, we provide a complete suite of services throughout the project lifecycle.

Proven Track Record

Conserve Solutions has a track record of successful projects in the oil and gas industry, demonstrating our capability to deliver on time and within budget.

Adaptability and Flexibility

We understand the dynamic nature of the oil and gas industry. Our team is adaptable and flexible, ready to meet the evolving requirements of your projects.

Frequently Asked Questions?

FEED is the initial phase of a project where the engineering design and planning are conducted to define the project scope, budget, and schedule before detailed engineering work begins.

3D Laser Scanning facilitates accurate as-built documentation, minimizing errors and rework during project execution. It enhances safety, reduces costs, and improves overall project efficiency.

Design considerations for offshore platforms include environmental conditions (e.g., wave height, wind speed), water depth, structural integrity, foundation design, equipment layout, and safety systems.

HAZOP studies systematically identify and assess potential hazards and operability issues in a project. This proactive approach helps in risk mitigation and ensures the safety and operability of the facility.

Environmental considerations involve compliance with regulations, impact assessments, and sustainable practices. We integrate environmental considerations into the engineering design to minimize ecological impact.