1. Background and Definition of Building Envelope

Building envelope thermal performance plays an important role in determining the cooling load and hence energy consumption and cost of the building. Building envelope can be classified into opaque and fenestration components.

Opaque components include external walls, roof, doors and ground.

Fenestration includes transparent parts of building envelope which includes windows, curtain walls and skylight.

In this article we will discuss about various insulation options to meet the regulatory requirements in Qatar

2. Building Envelope Regulatory requirements in Qatar

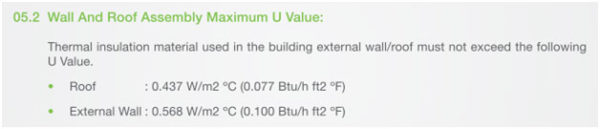

a. Municipality and KAHRAMAA Regulations:

b. Qatar Construction Standard 2014

Section 7 of QCS 2014 refers to GSAS, Global Sustainability Assessment System developed by GORD. QCS 2014 has made parts of GSAS a mandatory requirement. The mandatory requirements of QCS 2014 include Energy, Water and parts of Indoor Environment. Hence, building envelope should meet GSAS Energy Criteria. GSAS is a performance based system and hence does not provide any prescriptive requirements like KAHRAMAA. Projects should achieve a score of at least 0 to avoid non-compliance. This depends on various factors like Building Envelope thermal performance, Window-to-Wall ratio, Ventilation rates, LPD, etc.

The baseline U values used in GSAS Energy Calculators are as below:

- Roof U Value– 0.25 W/m2k

- External Wall– 0.3 W/m2k

3. Wall Assemblies

The wall section depends on whether the project requires compliance only with KAHRAMAA requirements or it is also looking to meet GSAS or LEED requirements

a. Autoclaved Aerated concrete block:

Autoclaved Aerated Concrete is a lightweight pre-cast concrete that contains air bubbles throughout the material to generate the low-density lightweight material blocks

The thermal conductivity of AAC blocks varies from 0.11 to 0.13 W/m. K. Generally 200mm block with light weigh plaster on either side shall meet the requirements of KAHRAMAA U value of 0.568 W/m2C

b. Insulated concrete block

Concrete blocks with Polystyrene insulation insert are very common in GCC market. 200mm block with 60mm polystyrene insulation will provide a U Value complying with KAHRAMAA regulations.

c. Pre-Insulated Sandwich Panels

Pre-Insulated sandwich panels are generally used in warehouses and industrial facilities for both wall and roof. Polyurethane is generally used as insulation between aluminum sheets.

d. Fiber glass insulation

The thermal conductivity of Fiber Glass Insulation available in the market is between 0.03 W/m. k to 0.04 W/mk. 50mm thick insulation is sufficient to comply with KAHRAMAA regulation. However, more thickness shall be required to meet GSAS or LEED requirements. Fiber glass insulations are relatively cheaper and is not inflammable reducing the risk of fire. Fiber glass insulation is to be handled carefully as it can cause damage to eyes, lungs etc.

e. Polyurethane rigidboard Insulation

Polyurethane board insulation is available in different thickness. It has very strong thermal resistance. The thermal conductivity of polyurethane available in the market is between 0.02 W/m. k to 0.03 W/m.k. 50mm polyurethane insulation is sufficient to comply with KAHRAMAA regulation. However more thickness shall be required to meet GSAS or LEED requirements. It is fire resistant.

f. Polystyrene insulation

Polystyrene board insulation is available in different thickness. The thermal conductivity of polystyrene available in the market is between 0.03 W/m. k to 0.045 W/m. k.50mm thick insulation is sufficient to comply with KAHRAMAA regulation. However more thickness shall be required to meet GSAS or LEED requirements.

4. Roof Assemblies:

Polyurethane insulation boards of thickness 75 mm to 100 is generally used in roof. 75mm is sufficient to meet KAHRAMAA regulations and 100mm insulation is required for projects targeting GSAS or LEED certifications.

Conserve Solutions will be happy to assist your projects. Our offices are located in India, UAE, Qatar, Saudi Arabia, Canada, United Kingdom, Egypt and Singapore.

Author

-

Mr. K M Bazeeth Ahamed is an USGBC LEED Faculty & consultant in Green Buildings. He has completed his Post Graduation in Mechanical Engineering from Birla Institute of Technology in 2002 and has spent 12 years in Academics, Research, MEP Contracting, Energy Audits and Green Building Consultancy.