Conserve offers building envelope design and simulation services in Qatar and UAE offices.

Our building envelope design and simulation or Hygro-Thermal design & analysis services include:

Thermal protection design

Moisture protection design

Hygro-Thermal Analysis:

Optimizing hygro-thermal performance of building envelope is vital for any buildings and especially for new constructions/major renovations within dry, sub-tropical climatic zones like Qatar and rest of the middle-east. Basis of Hygro-thermal design analysis lies on proper selection & arrangement of enclosure materials and involves two key components as below:

1. Thermal protection design:

Thermal performance of building envelope components contributes to significant cooling load through conductive (for opaque elements) and radiative heat transfer (for glazing). Also local building codes (E.g. QCS 2014 Section 15 – Insulation of Buildings) and green building rating systems (E.g. LEED, GSAS) mandates certain U-value requirements for different building envelope components.

Team Conserve’s vast experience with properties and cost of various insulation materials (E.g. Rockwool, Polystyrene, Poly-isocyanurate, Phenolic, etc.) available in the market is helping our clients in selecting material with required dimensions and properties to avoid cost incurred with over-design, HVAC impacts associated with under-design.

For example, a typical wall (200mm block) with 65mm thick Phenolic insulation or 110mm thick Rockwool insulation will achieve a same U-value of 0.3 W/m2 . K. Selection of appropriate material to be validated against budget constraints, interfacing complexities with façade design (if applied externally) and influence in building carpet area (if applied internally).

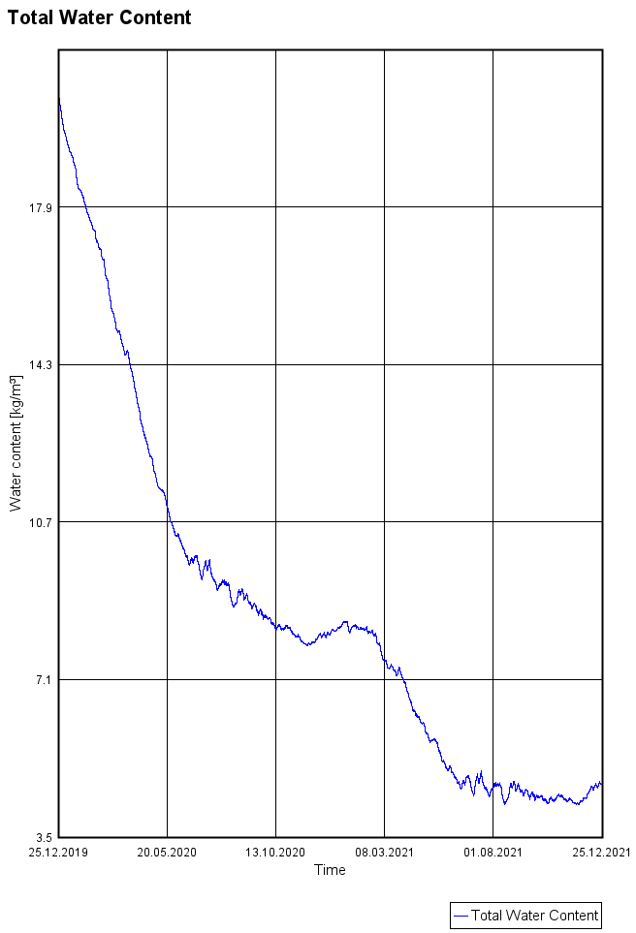

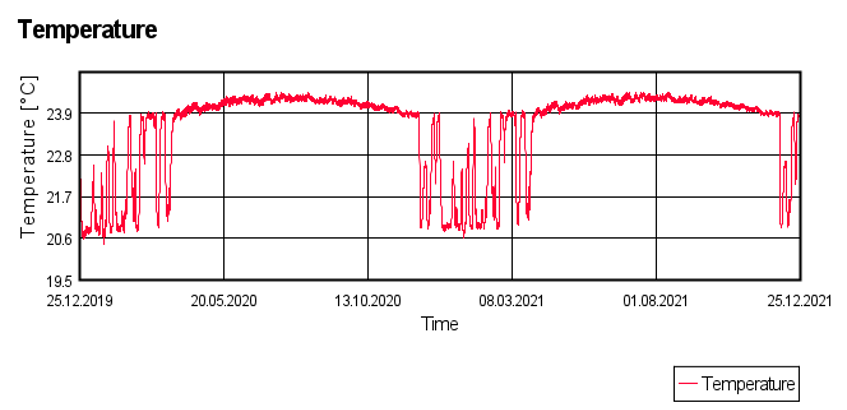

For example, a typical wall (200mm block) with 65mm thick Phenolic insulatIn addition to the above, key action in thermal protection design which most of the design consultants are missing to evaluate is the Life-cycle performance of building envelope which in-turn can adversely impact HVAC performance and thermal comfort of the occupants. Simulations to check deterioration in thermal performance over the years will help in assigning accurate safety factor during HVAC equipment selection. At this point it is worth to note that, HVAC over-design and associated equipment selection is still costing a lot to the contractor due to lack of coordination between HVAC and Building envelope designers. Below images represents thermal performance simulation of an education building over a period of two years:ion or 110mm thick Rockwool insulation will achieve a same U-value of 0.3 W/m2 . K. Selection of appropriate material to be validated against budget constraints, interfacing complexities with façade design (if applied externally) and influence in building carpet area (if applied internally).

2. Moisture protection design:

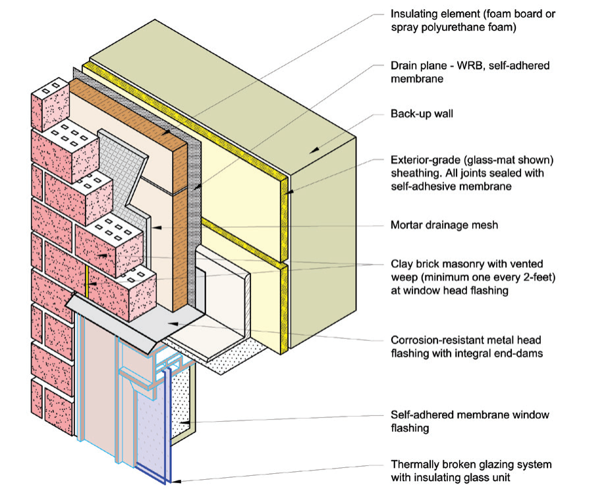

Moisture intrusion into the building envelope can reduce structural robustness, mold growth in building materials & HVAC components and can result in adverse health impacts to the occupants. Moisture protection design is climate dependent and lies on basic principles of controlling moisture entry, accumulation and drying from sources like rainwater, groundwater, air transport and vapor diffusion.

In hot-humid climates principal moisture concerns are rain penetration, groundwater and mold growth linked to high interior levels of humidity during cooling periods. Conserve’s building envelope specialist team follows 4-D technique (Deflection, Drainage, Drying and Durability) while designing to tackle or mitigate above concerns.

Image source: ‘Moisture Control Guidance for Building Design, Construction and Maintenance’ by U. S. Environmental Protection Agency

Selection of vapor barrier with Water diffusion resistance factor (µ) equal or better than local construction codes and proper layering within building envelope is key moisture protection design. In hydrological zones like Qatar, it is ideal to locate vapor diffusion retarders towards exterior to avoid moisture ingress from ambient and other building assemblies can be designed and built to dry to the interior. Below image represents water content simulation within a building envelope for an education building: