- Inspire

- Innovate

- Integrate

- Home

- Who we are

- Services

- Portfolio

- Training

Green Building Credential Courses

Classroom Courses

Course Materials New

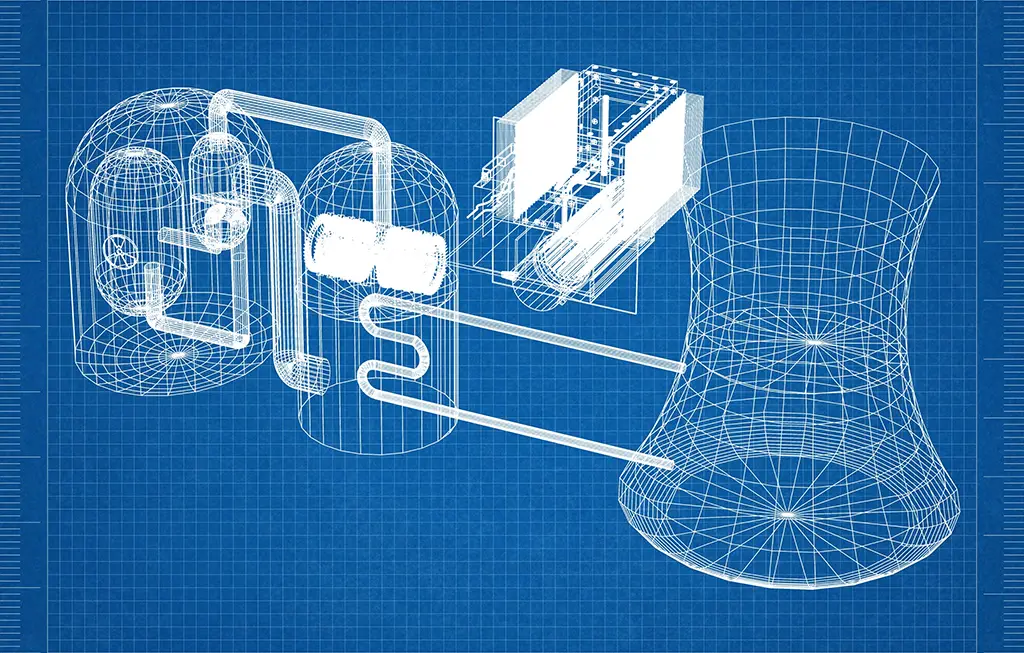

Engineering Courses

- Robotics -for Little Engineers New

- MEP Engineering Training Course Qatar New

- Fire Fighting New

- Plumbing Training Course with Certification New

- Heating Ventilation & Air-conditioning New

- 3D laser Scanning Training Course Qatar New

- Plumbing & Fire Fighting

- Electrical Design Course

- Piping Design Engineering Training Course

- Piping Design course – Piping Simulation Analysis Training

- Energy Modeling & Simulation Course

- Blog

- Careers

- Contact Us